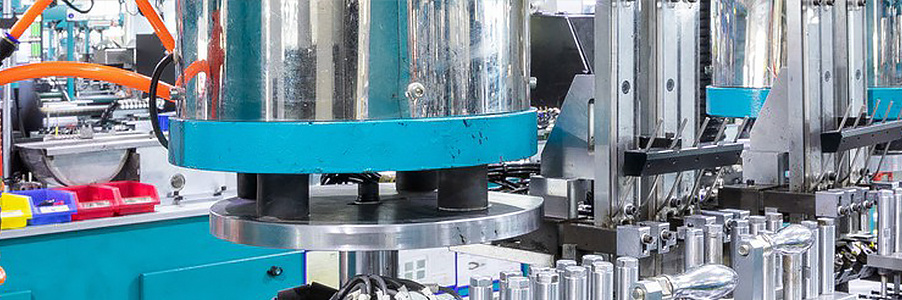

Quality assurance

Strong technical strength, good quality, delivery management and after-sales service are the guarantee for xiongli team to serve every customer wholeheartedly

Pursue excellent quality, continuous improvement, full participation, and fully meet customer requirements.

Pursuit of excellence: there is no best, only better. Customer expectations are the driving force behind our progress. We listen to the voice of customers, perceive their expectations, and respond to customer needs with better service quality, lower operating costs, and faster speed, and pursue and achieve excellence in management and service.

Continuous Improvement: Quality improvement is endless. For the improvement of our services, the first priority is to establish the improvement mechanism, and the second is to maintain the operation of the improvement mechanism. We believe that the occurrence of most service problems must be found at the mechanism level; the solution to the vast majority of service problems must be found at the mechanism level. The business environment is constantly changing, and customer expectations are constantly rising. To achieve customer satisfaction, our basic strategy is continuous improvement.

Participation of all staff: The success of quality control and quality assurance depends on the soundness and perfection of the quality control system, and also on the solid implementation and improvement of all staff. We pay attention to the improvement of employees' quality awareness and quality skills. Every employee firmly believes in "producing products that satisfy both themselves and customers", and resolutely does not accept, manufacture or hand over substandard products. The down-to-earth execution of all staff and the tireless improvement of all staff are our important competitive weapon and the guarantee of our perfect service for every customer.

Meet customer requirements: We have experienced quality engineers, QC, and a full set of testing equipment. Such as high-precision three-dimensional (accuracy up to 0.001mm), conventional testing equipment such as projectors, to ensure that the molds and products produced can meet customer requirements.